These neodymium pot magnets with countersunk holes have only one surface that has strong magnetism; the other surface of the neodymium pot magnets just has very weak magnetism.

Leyuan countersunk neodymium magnets have excellent holding forces thanks to the use of anisotropic neodymium (NdFeB) magnets. The maximum working temperature of these types is up to 80°C, and the steel body is galvanized. These types are used in applications where high holding forces and small dimensions are required.

Application: magnet source round base magnets can be inserted into different instruments, machines, and tools. These mountable magnets can be used effectively as auxiliary instruments during transport, clamping, mounting, lifting, welding, separation, etc. The best holding force is reached at full contact of the magnetic face with the ground ferromagnetic surface. Force is vertical to the base (air gap = 0 mm). Small cracks on the magnet or steel pot do not have any influence as to the functionality, lifetime, and holding force of the pot magnet.

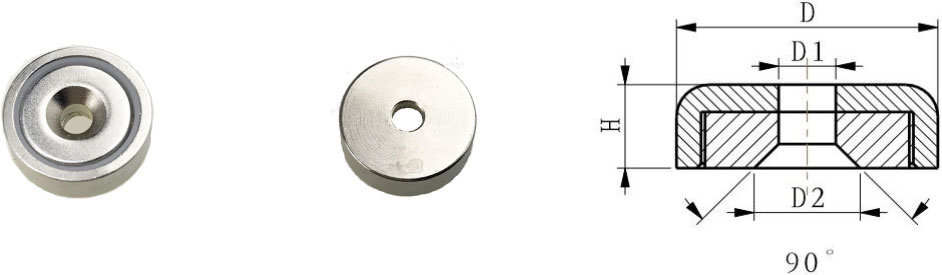

Counterbore Stamp

Counterbore Lathe

Straight Hole Stamp

Straight Hole Lathe

Model | D | D1 | D2 | H | Weight (g) | Pull force (Kgf) |

103-16 | 16 | 3.5 | 6.5 | 5.2 | 7 | 6 |

103-20 | 20 | 4.5 | 8.6 | 7.2 | 15 | 9 |

103-25 | 25 | 5.5 | 10.6 | 7.7 | 24 | 19 |

103-32 | 32 | 5.5 | 10.6 | 7.8 | 39 | 32 |

103-36 | 36 | 6.5 | 12 | 7.6 | 50 | 41 |

103-40 | 40 | 6.5 | 12 | 7.8 | 69 | 52 |

103-42 | 42 | 6.5 | 12 | 8.8 | 77 | 61 |

103-48 | 48 | 8.5 | 19 | 10.8 | 120 | 75 |

103-60 | 60 | 8.5 | 19 | 15 | 243 | 115 |

103-75 | 75 | 10.5 | 21 | 17.8 | 480 | 163 |

103-16L | 16 | 3.5 | 6.5 | 5.2 | 7 | 5 |

103-20L | 20 | 4.5 | 8.6 | 6 | 13 | 8 |

103-25L | 25 | 5.5 | 10.6 | 6.9 | 23 | 17 |

103-32L | 32 | 5.5 | 10.6 | 6.8 | 38 | 30 |

103-36L | 36 | 6.5 | 12 | 6.9 | 50 | 39 |

103-42L | 42 | 6.5 | 12 | 7.9 | 78 | 58 |

103-48L | 48 | 8.5 | 19 | 9.6 | 113 | 72 |

103-60L | 60 | 8.5 | 19 | 15 | 265 | 115 |

103-75L | 75 | 10.5 | 21 | 17.8 | 537 | 163 |

103-16P | 16 | 3.5 | 6.5 | 5.2 | 7 | 8 |

103-20P | 20 | 4.5 | 8.6 | 7.2 | 15 | 11 |

103-25P | 25 | 5.5 | 10.6 | 7.7 | 24 | 24 |

103-32P | 32 | 5.5 | 10.6 | 7.8 | 39 | 40 |

103-36P | 36 | 6.5 | 12 | 7.6 | 50 | 51 |

103-40P | 40 | 6.5 | 12 | 7.8 | 69 | 65 |

103-42P | 42 | 6.5 | 12 | 8.8 | 77 | 76 |

103-48P | 48 | 8.5 | 19 | 10.8 | 120 | 94 |

103-60P | 60 | 8.5 | 19 | 15 | 243 | 144 |

103-75P | 75 | 10.5 | 21 | 17.8 | 480 | 204 |

Model | D | D1 | D2 | H | Weight (g) | Pull force (Kgf) |

104-10 | 10 | 3.5 | 6.5 | 5 | 3 | 1 |

104-12 | 12 | 3.5 | 6.5 | 5 | 4 | 1.5 |

104-14 | 14 | 3.5 | 6.5 | 4.5 | 5 | 4 |

104-16 | 16 | 3.5 | 6.5 | 5.2 | 7 | 6 |

104-18 | 18 | 4.5 | 8.6 | 6 | 10 | 8 |

104-20 | 20 | 4.5 | 8.6 | 7.2 | 15 | 9 |

104-22 | 22 | 4.5 | 8.6 | 6.9 | 18 | 15 |

104-25 | 25 | 5.5 | 10.6 | 7.7 | 24 | 19 |

104-28 | 28 | 5.5 | 10.6 | 6.4 | 28 | 25 |

104-30 | 30 | 5.5 | 10.6 | 6.4 | 32 | 29 |

104-32 | 32 | 5.5 | 10.6 | 7.8 | 39 | 32 |

104-34 | 34 | 5.5 | 10.6 | 7.3 | 45 | 35 |

104-36 | 36 | 6.5 | 12 | 7.6 | 50 | 41 |

104-38 | 38 | 6.5 | 12 | 7.4 | 60 | 47 |

104-40 | 40 | 6.5 | 12 | 7.8 | 69 | 52 |

104-42 | 42 | 6.5 | 12 | 8.8 | 77 | 61 |

104-45 | 45 | 6.5 | 12 | 8.7 | 90 | 70 |

104-48 | 48 | 8.5 | 19 | 10.8 | 120 | 75 |

104-50 | 50 | 8.5 | 19 | 10.7 | 136 | 89 |

104-55 | 55 | 8.5 | 19 | 12 | 192 | 102 |

104-60 | 60 | 8.5 | 19 | 15 | 243 | 115 |

104-65 | 65 | 8.5 | 19 | 14.9 | 338 | 130 |

104-70 | 70 | 10.5 | 21 | 16.9 | 440 | 148 |

104-75 | 75 | 10.5 | 21 | 17.8 | 480 | 163 |

104-80 | 80 | 10.5 | 21 | 19 | 655 | 250 |

104-90 | 90 | 10.5 | 21 | 18 | 822 | 340 |

104-100 | 100 | 12.5 | 25 | 18 | 1030 | 380 |

104-110 | 110 | 12.5 | 25 | 18 | 1226 | 420 |

104-120 | 120 | 12.5 | 25 | 18 | 1420 | 480 |

Model | D | D1 | D2 | H | Weight (g) | Pull force (Kgf) |

105-16 | 16 | 3.5 | 6.5 | 5.2 | 7 | 5 |

105-20 | 20 | 4.5 | 8 | 7.2 | 13 | 8 |

105-25 | 25 | 5.5 | 9 | 7.7 | 22 | 17 |

105-32 | 32 | 5.5 | 9 | 7.8 | 38 | 30 |

105-36 | 36 | 6.5 | 11 | 7.6 | 48 | 40 |

105-40 | 40 | 6.5 | 11 | 7.8 | 69 | 50 |

105-42 | 42 | 6.5 | 11 | 8.8 | 75 | 65 |

105-48 | 48 | 8.5 | 15 | 10.8 | 114 | 72 |

105-60 | 60 | 8.5 | 15 | 15 | 235 | 110 |

105-75 | 75 | 10.5 | 18 | 17.8 | 460 | 155 |

105-16L | 16 | 3.5 | 6.5 | 5.2 | 7 | 4 |

105-20L | 20 | 4.5 | 8 | 6 | 12 | 7 |

105-25L | 25 | 5.5 | 9 | 6.9 | 23 | 16 |

105-32L | 32 | 5.5 | 9 | 6.8 | 38 | 28 |

105-36L | 36 | 6.5 | 11 | 6.9 | 50 | 38 |

105-42L | 42 | 6.5 | 11 | 7.9 | 76 | 62 |

105-48L | 48 | 8.5 | 15 | 9.6 | 111 | 69 |

105-60L | 60 | 8.5 | 15 | 15 | 260 | 110 |

105-75L | 75 | 10.5 | 18 | 17.8 | 524 | 155 |

105-16P | 16 | 3.5 | 6.5 | 5.2 | 7 | 6 |

105-20P | 20 | 4.5 | 8 | 7.2 | 13 | 10 |

105-25P | 25 | 5.5 | 9 | 7.7 | 22 | 21 |

105-32P | 32 | 5.5 | 9 | 7.8 | 38 | 38 |

105-36P | 36 | 6.5 | 11 | 7.6 | 48 | 50 |

105-40P | 40 | 6.5 | 11 | 7.8 | 69 | 63 |

105-42P | 42 | 6.5 | 11 | 8.8 | 75 | 81 |

105-48P | 48 | 8.5 | 15 | 10.8 | 114 | 90 |

105-60P | 60 | 8.5 | 15 | 15 | 235 | 150 |

105-75P | 75 | 10.5 | 18 | 17.8 | 460 | 213 |

Model | D | D1 | D2 | H | Weight (g) | Pull force (Kgf) |

106-10 | 10 | 3.5 | 6.5 | 5 | 2 | 1 |

106-12 | 12 | 3.5 | 6.5 | 5 | 4 | 1.5 |

106-14 | 14 | 3.5 | 6.5 | 4.5 | 5 | 3 |

106-16 | 16 | 3.5 | 6.5 | 5.2 | 7 | 5 |

106-18 | 18 | 4.5 | 8 | 6 | 10 | 6 |

106-20 | 20 | 4.5 | 8 | 7.2 | 13 | 8 |

106-22 | 22 | 4.5 | 8 | 6.9 | 17 | 16 |

106-25 | 25 | 5.5 | 9 | 7.7 | 22 | 18 |

106-28 | 28 | 5.5 | 9 | 6.4 | 27 | 23 |

106-30 | 30 | 5.5 | 9 | 6.4 | 32 | 27 |

106-32 | 32 | 5.5 | 9 | 7.8 | 38 | 30 |

106-34 | 34 | 5.5 | 9 | 7.3 | 44 | 33 |

106-36 | 36 | 6.5 | 11 | 7.6 | 48 | 40 |

106-38 | 38 | 6.5 | 11 | 7.4 | 59 | 44 |

106-40 | 40 | 6.5 | 11 | 7.8 | 69 | 50 |

106-42 | 42 | 6.5 | 11 | 8.8 | 75 | 65 |

106-45 | 45 | 6.5 | 11 | 8.7 | 89 | 69 |

106-48 | 48 | 8.5 | 15 | 10.8 | 114 | 72 |

106-50 | 50 | 8.5 | 15 | 10.7 | 134 | 81 |

106-55 | 55 | 8.5 | 15 | 12 | 189 | 93 |

106-60 | 60 | 8.5 | 15 | 15 | 235 | 110 |

106-65 | 65 | 8.5 | 15 | 14.9 | 333 | 122 |

106-70 | 70 | 10.5 | 18 | 16.9 | 429 | 138 |

106-75 | 75 | 10.5 | 18 | 17.8 | 460 | 155 |

106-80 | 80 | 10.5 | 18 | 19 | 641 | 250 |

106-90 | 90 | 10.5 | 23 | 18 | 799 | 340 |

106-100 | 100 | 12.5 | 25 | 18 | 1016 | 380 |

106-110 | 110 | 12.5 | 25 | 18 | 1212 | 420 |

106-120 | 120 | 12.5 | 25 | 18 | 1380 | 480 |

Pot magnets can be inserted into different instruments, machines, tools. Can be used as auxiliary instruments during transport, clamping, mounting, lifting, welding, separation, etc. The best holding force is reached at full contact of the magnetic face with the ground ferromagnetic surface, force is vertical to the base (air gap = 0 mm). Small cracks on the magnet or steel pot do not have any influence to the functionality, lifetime and holding force of the pot magnet.

Other Magnetic Products You May Also Like

Related Blogs

Leyuan Video Show

START NOW

Email us with any questions or inquiries or use our contact data. We would be happy to answer your questions.